How to Put Belt Back on 6.0 Powerstroke

Written By: Lawrence "LT" Tolman

7.3 Powerstroke 1994 To 2003: The Big Block of Diesels

You've heard the phrase "bigger is better" many times in your life, especially when talking about engines. In the early 90's when Dodge and Chevy were putting mere 5.9- and 6.5-liter diesels into their trucks, Ford raised the bar with its juggernaut powerplant, the 7.3-liter Powerstroke. To this day, it remains the largest displacement diesel engine ever installed from the factory into a pickup, but the question remains: was bigger truly better? Why hasn't anyone come close to matching its displacement? The two runners up are the 6.7-liter Cummins and Powerstroke, but those are still 36 cubic inches smaller than the 7.3-liter behemoth. While it was never known to be a racehorse, its reputation was that of being one of the most reliable and overbuilt engines to hit the road in a production truck, but as always, you've got to wonder, what breaks when? Well today, we're gonna find out.

What Makes It Tick

The 7.3-liter Powerstroke is often confused with the 7.3-liter IDI which was used in Ford pickup trucks from 1988 to 1994. Both were manufactured by Navistar International, but there were several key differences that made the Powerstroke superior to the IDI version, and top of the list was the addition of direct injection. While the Cummins engines of the day used a poppet injector, Ford (technically International) used a design which has seen heavy use in commercial and industrial engines, HEUI, or Hydraulic Electronic Unit Injection. It's an oddball design which actually works quite well, and its advantage over mechanical injection pumps like the P7100 is its ability to vary injection timing for a broader power curve.

Inside the engine is a conventional oil pump which lubricates all the critical moving parts, but there is also a second oil pump. The High-Pressure Oil Pump (or HPOP) uses the same oil as the low-pressure system, except now its pressurized up to 3,000 PSI and fed through an oil rail which is common to all eight injectors. All at the same time, low pressure diesel fuel is sent from the tank to the engine via a lift pump, through a couple filters, into the cylinder heads, and it winds up in the injectors in a cavity opposite the oil, which is where the magic happens. When it's time to start the injection event, an electronic solenoid opens a valve allowing oil to flow, which pushes down on a plunger and forces the fuel into the engine. Because of the differing surface areas of each side of the plunger, there is a pressure multiplication of 7:1, which means 3,000 psi of oil pressure gets converted into 21,000 psi of fuel.

One unique feature of an HEUI system is the built-in fail-safe of never being able to run the engine without oil. If you spring a massive leak and the oil level drops below 7 quarts, the HPOP won't be able to generate the required pressure, and the engine simply won't run saving you from potential bearing damage (although if all 14 quarts leak out at once, you might get a visit from the EPA's disaster response team). Aside from the injection system, the rest of the Powerstroke is pretty standard. It features two valves per cylinder, a compression ratio of 17.5:1, and power varied between 210 and 275 horsepower, and the torque figures went from 425 to 525 foot pounds of torque over the nine year production run which ended in 2003 with a little over two million 7.3's produced.

Got 73 Problems…

Mechanically, a 7.3 is about as bulletproof as they come, and rarely will you have a severe mechanical failure. The rotating assembly is solid, the heads are securely bolted to the block, and just about any moving part has a service life longer than the rest of the truck will last. There are, however, a few small issues associated with the HEUI system which might leave you stranded a time or two. Most of them are inexpensive fixes and easy for a DIY'er to take care of without a lot of effort. In fact, the biggest problem you might have while owning a 7.3 is keeping all the acronyms straight.

IPR Valve (Injection Pressure Regulator Valve)

The Injection Pressure Regulator valve is physically bolted to the high-pressure oil pump and acts just like a Fuel Control Actuator on a CP3. Based on how much oil pressure is needed, the IPR receives commands from the ECM and meters how much oil is allowed to enter the HPOP, thereby controlling the pressure output. The minimum oil pressure necessary for the 7.3 to run is 500psi, and under wide open throttle it should be around 3,000. To achieve its target, the duty cycle of the solenoid is constantly varied. Since its both an electronic and mechanical part, the IPR solenoid is known to fail, and as it does, you'll notice rough running, surging, stalling, and sometimes a no-start condition. It can fail for several reasons, whether it be a damaged O-ring, sticking valve, or fault in the internal wiring. Regardless of which case you have, there is a solution. If all you have is a bad O-ring, you can pick up a seal kit for about fourteen bucks, or if you have an internal fault, you can get a whole new valve for just over $200.

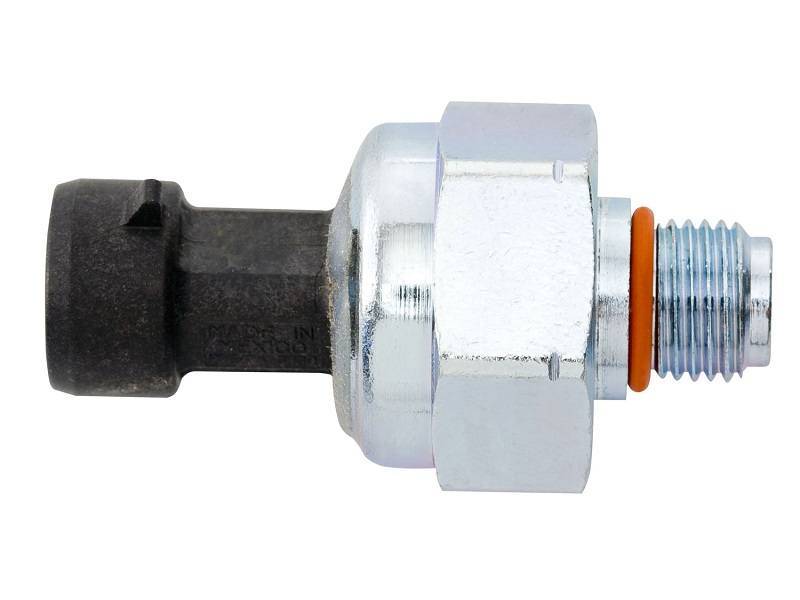

ICP Sensor (Injection Control Pressure Sensor)

The IPR controls how much high-pressure oil you get, but it's the Injection Control Pressure sensor which tells the computer how much pressure there actually is. Without this information, the ECM wouldn't be able to precisely control the operation of the engine since there'd be no feedback; you can think of the ICP as an O2 sensor of sorts. On a 7.3 its located on the driver's side cylinder head towards the front of the engine, and it's pretty easy to access in the event of a failure. Speak of which, if the ICP is on its way out, you'll notice hard starting, rough running, surging, missing, or not starting altogether. You'll quickly notice most parts that fail on a 7.3 will exhibit similar symptoms, but there are several ways to narrow it down to the ICP. You might have a check engine light with one or more codes (P2283, P2284, or P2286), but the DTC's don't always pop up. If you unplug the electrical connector and see oil, that's a dead giveaway of a failure, finally you can just unplug the sensor at the time your truck is running and see if there's a noticeable change in the idle sound. Normally, if you unplug the ICP sensor, the pressure will go from its idle range of 550 to about 750psi, and this spike will change how the motor sounds, and if there's no change, it means you have a failed sensor. If the ICP is faulty, you will be back in business in no time, since it easily swaps out with basic hand tools, and a new ICP sensor can be purchased for just over one hundred dollars.

UVCH/IDM (Under Valve Cover Harness/Injector Drive Module)

In order to fire an injector and kick off a combustion event, the signal first comes from the ECM, but it can't generate the required power to fire the injectors by itself. Even though the rest of the truck operates at 12 volts DC, the injectors are designed with an operating range of 100 to 110 VDC so another module is needed to amplify the signal and make the injectors work. This is where the 7.3 IDM or Injector Driver Module comes into play. It takes the low voltage signal from the ECM, and with some electronic wizardry, is able to output a much higher voltage. The power passes through a special part of the wiring called the UVCH (Under Valve Cover Harness) where it goes from outside to inside the motor, and ultimately winds up at an injector.

Because of its location under the valve cover inside a hot engine, in a high-vibration environment, the UVCH is known to rub though or break the wire's insulation which can interrupt the signal heading to the injector. As you can guess, the symptoms of a bad harness include rough running, but it will be isolated to one or two cylinders and not the whole engine. If you have access to a scan tool, you can run a cylinder contribution test to ID the side, or if you are comfortable with a DVOM you can ohm out the wires between the connector pin and ground to see which bank has failed. Once again, the benefit of owning an older truck shows up since a replacement UVCH only costs $66. For that much, you might as well buy both sides, since if one is worn, likely the other isn't too far behind.

While not as common, the IDM itself has been known to fail also, and if it does, you'll have a similar symptom as a broken UVCH,, and a few codes as well. If you do need a replacement module and are interested in extra power and a more responsive engine, a smart move would be upgrading to a modified IDM. With a few changes to the internal circuitry, the output voltage is raised, and the result is about 30 extra horsepower at the rear wheels.

Other Issues

Most problems that you'll have on a 7.3 are related to the high-pressure oiling systems, but there are a couple other small problems. If you have a smooth-running truck and it suddenly has a loss of power and smells like exhaust inside the cab, you need to look underneath the turbocharger, as likely you have a failed-up pipe connection. From the factory, a "crush donut" was used as a seal between the up pipe and turbo, but it's prone to blowing out and leaking. While you could just replace the donut or even weld the pipes solid, a more reliable solution is to replace the stock up pipes and turbo Y adapter with some BD-Power up pipes. Be forewarned however, the up pipes are hard to get to: usually the transmission has to be removed in order to gain access, but some people have had success by removing a few body mount bolts and jacking up the cab. Up pipes are especially difficult to get to on an OBS Ford, since the clearances are so tight between the firewall and engine.

One negative side effect to the HEUI system is how hard it works your engine oil. Its common practice to keep the drain interval around 3-4 thousand miles since sludge and buildup can occur inside the injectors, which may lead to (surprise) rough running. In some cases, an injector can display symptoms which indicate it has failed, but the internal moving parts may just be stuck. Rather than replacing an injector, first give Hot Shot's Secret Stiction Eliminator a try. It's an oil additive which was designed with HEUI engines in mind and can clean out the deposits inside the engine and free up the insides of your injectors, saving a ton of money. It's not a cure all but is certainly worth a try at $32. I mean, most of us spend more than that at lunch every day.

Add More Power?

Let's say you have your old Powerstroke tuned up and running smooth, all the common problems have been taken care of, and now you want to make it faster. Right off the bat, you should realize you're barking up the wrong tree, but then, "fast" is a relative term. There have been a few people who have successfully taken a 7.3 over the magic one-thousand horsepower figure, but you can likely count those people on your fingers and toes. Even though there is plenty of aftermarket support for the 7.3, most people will make it to the 400whp mark and call it a day. Considering most stock trucks dyno around 160hp at the wheels, 400 is a very solid goal, and represents a gain of about 240 extra hp. For that benchmark, you'll need a few basic parts. Like any gas or diesel, you will start with airflow upgrades like a 7.3 Powerstroke cold air intake and free flowing exhaust, but those will only get you so far.

Modern common rail trucks are very easy to tune and can make tons of power with nothing more than a reflash, but it's hard to find a good custom calibration for a 7.3. Box programmers do OK on a stock truck, but once you start changing hard parts, you'll need to get custom. DP-Tuner writes tunes for the 7.3's which will be tailored to your trucks specific needs, whether your truck is stock or highly modified. The best part is they're loaded on a TS 6-position chip, so within a second or two, you can change from stock, to high idle, towing, hot tow, race, or the big tune.

The HEUI system will need some attention if you want to make it to 400hp or more, and that's simply because it takes more oil to fire the injectors longer and make more power. You can start at the heart of the system and ditch the stock (and likely high mileage) pump for an Adrenaline HPOP which has a much greater oil volume than stock. The great thing is, if you are replacing a failed pump you can run the Adrenaline HPOP with stock injectors, but it will also flow enough oil to support a larger set of injectors as well.

In regards to fueling your diesel, it's a delicate balance between enough fuel to meet your goals, and too much fuel which leads to excessive exhaust gas temps. A set of Dynomite Diesel Stage 2 Ford 7.3 injectors will add about 100 horsepower to your 7.3, can increase fuel mileage by about 1-2 MPG, and can be used with a stock 7.3 turbo. However, to get the most out of a larger injector you'll want to be pumping a little more air than the stock charger can supply. A BD Diesel Thruster II is the perfect 7.3 turbo upgrade to match for some 100hp injectors. It flows 40% more air than a stock turbo, is a direct bolt-in swap, and will give you more power, lower EGT's, and quick throttle response with no negative side effect like compressor surge.

Its important to note the OBS F-250 and 350 (1994.5 to 1997) was not equipped with an intercooler; the compressor discharge went straight into the engine. Hot air from the turbo is much less dense, which means it can contain less fuel (and make less power). There isn't a ton of extra space behind the grille, but luckily Banks Power offers a Techni-cooler intercooler system which easily installs, removes a ton of heat from the compressed air, cools off the exhaust gas, improves fuel economy, and the included twin ram 7.3 intake manifold makes for an even distribution of air between the two cylinder banks.

One last thing to consider are the connecting rods. The earlier OBS trucks used a forged rod, which is good for around 600 horsepower, but the later Superduty-era 7.3's were mostly equipped with a weaker powdered metal rod which is only good for around 450 horses. There was some overlap at the time of the transition and there's no clear manufacturing cut-off date, so if you're not sure what type of rod your engine has, you'll have to crawl underneath the truck and scrape the grease off an ID tag to run the numbers. It should go without saying, you need to plan your power goals according to what your engine will support.

All Dinosaurs Went Extinct…

Even though the 7.3 is a very reliable workhorse of an engine, it eventually was phased out. Partly due to emissions regulation, it was replaced with the 6.0 Powerstroke which still used the same HEUI style injection. Initially the 6.0 was supposed to be more reliable, but we've all heard the horror stories and know the truth about the plethora of problems the six-liter has. That's part of the reason why the 7.3 is still so loved to this day. Out of the two million plus units manufactured, many are still on the road and will be for a long time to come. If you are considering buying or building one, just remember to have realistic expectations. If you want a 600hp Ford, you might consider starting with a 6.4 or even a 6.7L Powerstroke, since they can build power so much easier. But, if you just want a reliable and efficient powerplant that doesn't break the bank, the 7.3 just might be the diesel for you.

7.3 Powerstroke Specs:

- Displacement: 444 Cubic Inches

- Block/Head Material: Cast Iron

- Compression Ratio: 17.5:1

- Firing Order: 1-2-7-3-4-5-6-8

- Bore: 4.11″

- Stroke: 4.18″

- Factory Intercooler: First introduced in 1999 model years

- Fuel Injection: HEUI (Hydraulic Electronic Unit Injection) – Basically the injectors are fired based upon oil pressure

- Valves: 16 (2 per cylinder)

- HP/TQ Ratings:

- 1994.5-1997: 210HP/425TQ

- 1999-2003: 275HP/525TQ

- Available Transmission Options:

- 1994.5-1997

- Manual: ZF5

- Automatic: E4OD

- 1999-2003

- Manual: ZF6

- Automatic: 4R110

- 1994.5-1997

How to Put Belt Back on 6.0 Powerstroke

Source: https://www.dieselpowerproducts.com/blog/what-breaks-when-ford-7-3l-powerstroke/